Accessories

Original accessories for pizza ovens

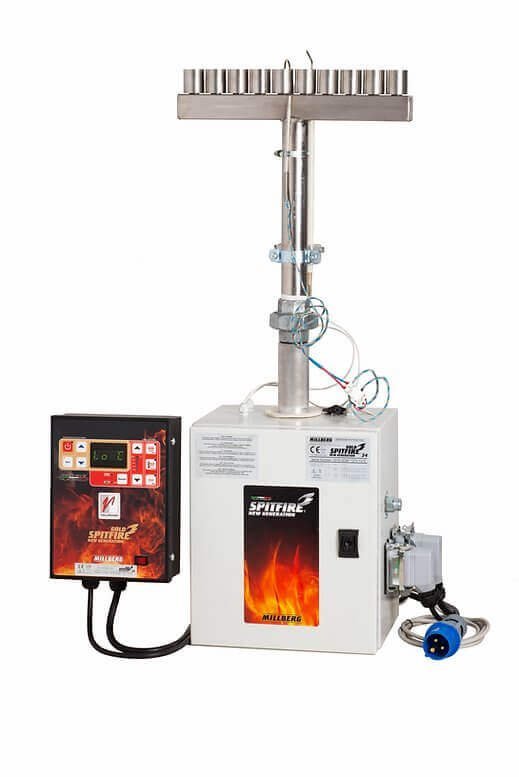

You have purchased one of our high quality stoves and are now looking for the right accessories or need a replacement for a proven product. With us you will find accessories of the brands Spitfire, Bernardi, Smoki, GI Metal, Coldline as well as Josper, Valoriani and Fontana. Whether it is insulation, Josper charcoal, which we also offer to restaurateurs on a subscription basis, or pizza shovels, dough kneading machines, gas fan burners, flue gas scrubbers, fireclay bricks or baking trays. With us you will find not only the high-quality original product, but also expert advice and years of experience. And if you have any questions, you can reach us by phone or mail at any time.