delivery time: 2-5 days

Delivery Time:

After your request you will receive an offer from us by e-mail.

Art.Nr.: R36

Buy easily and conveniently by invoice or installment via:

Show this product to your friends and acquaintances:

Reviews

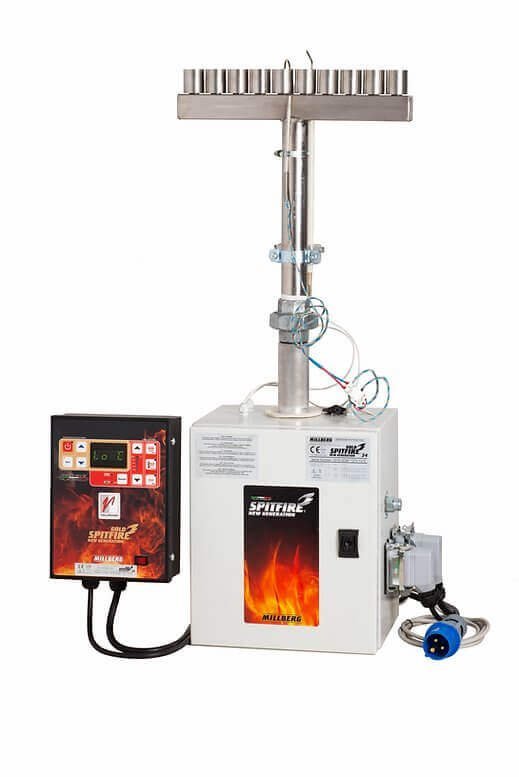

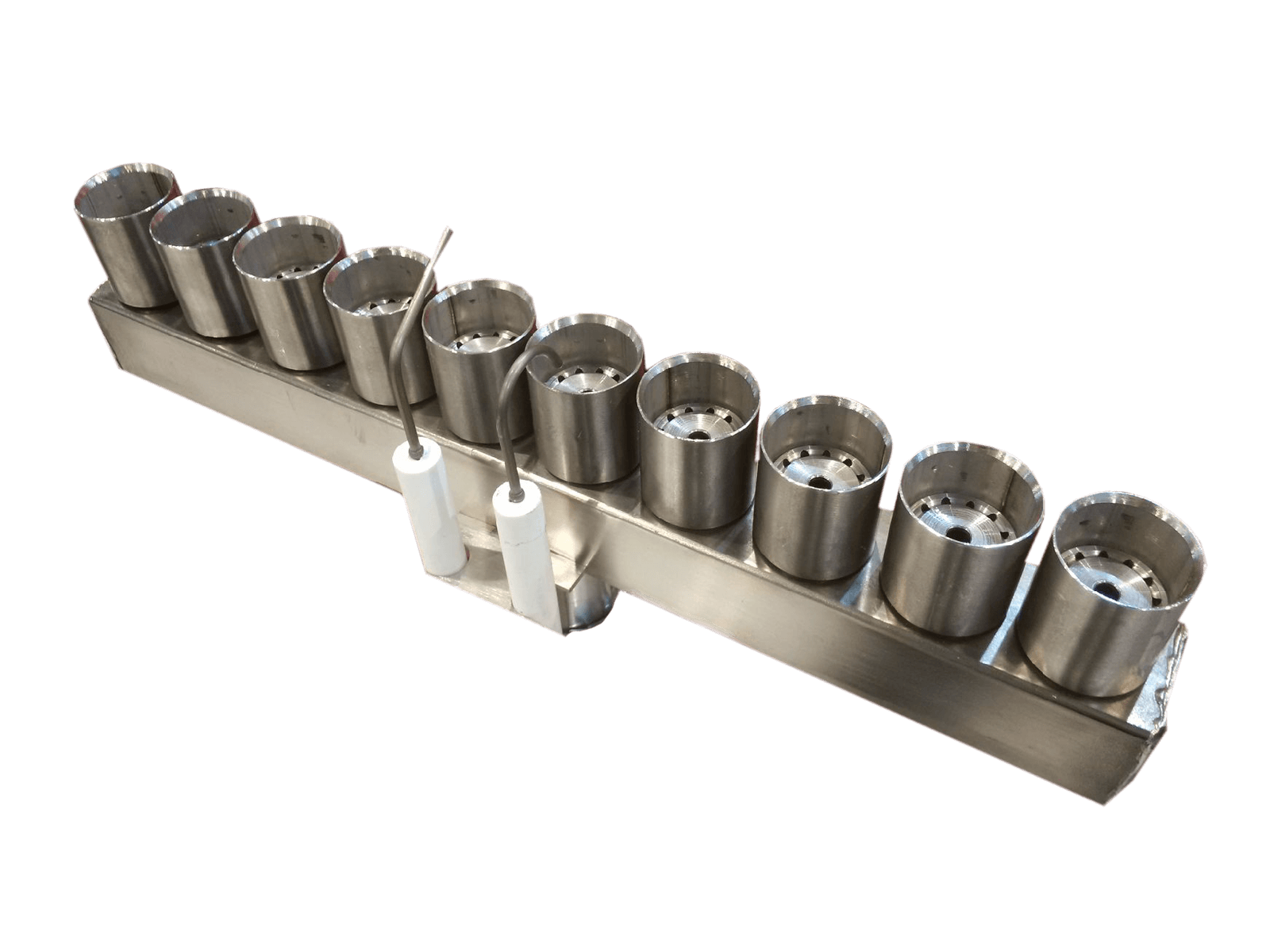

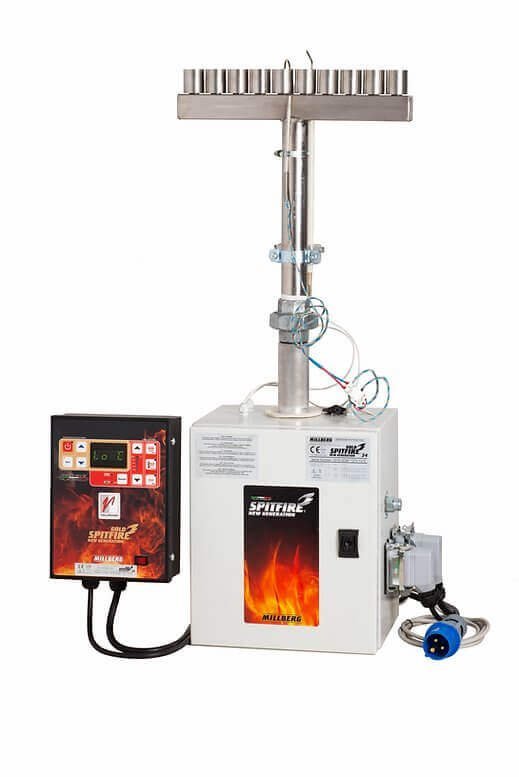

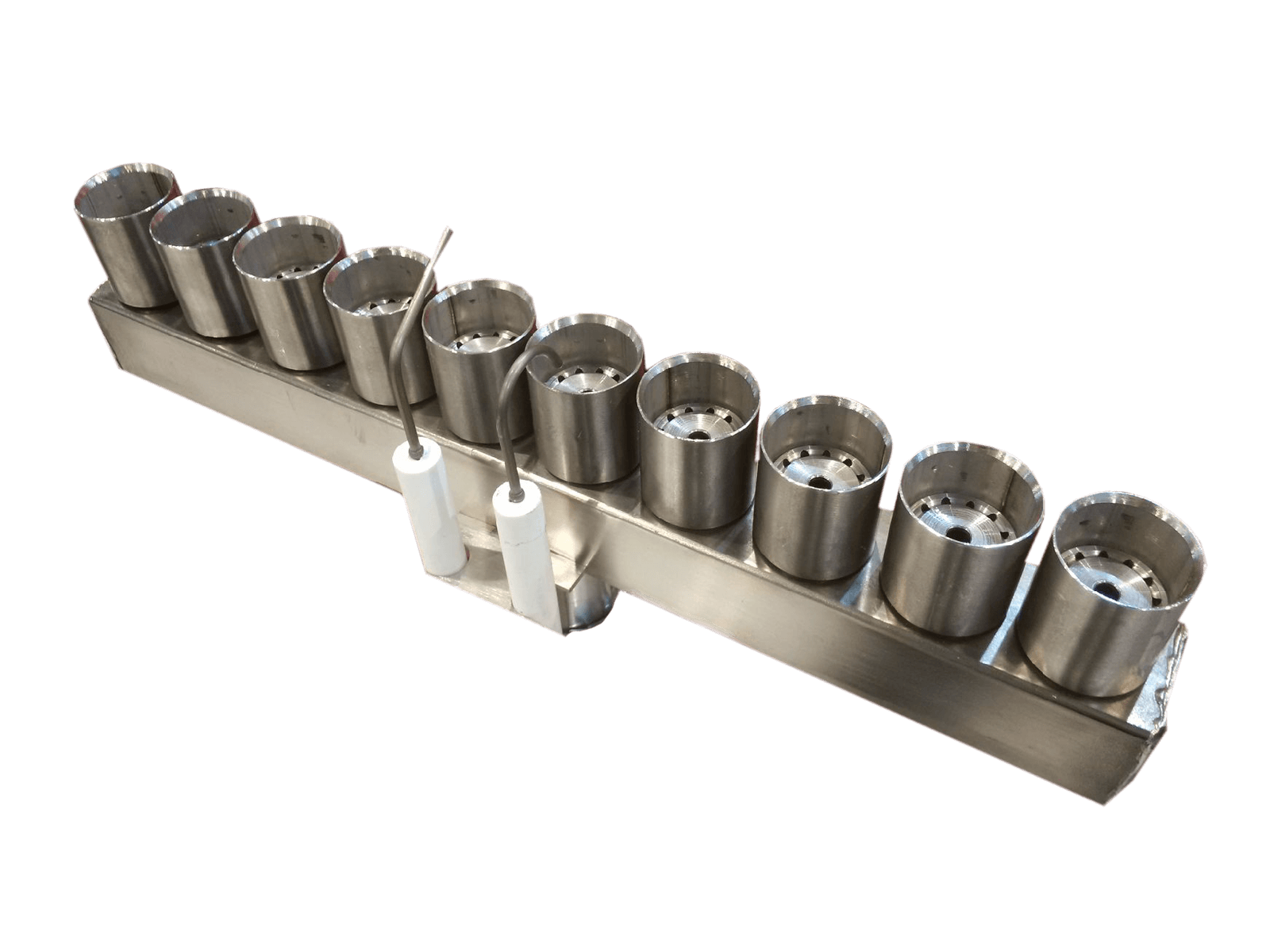

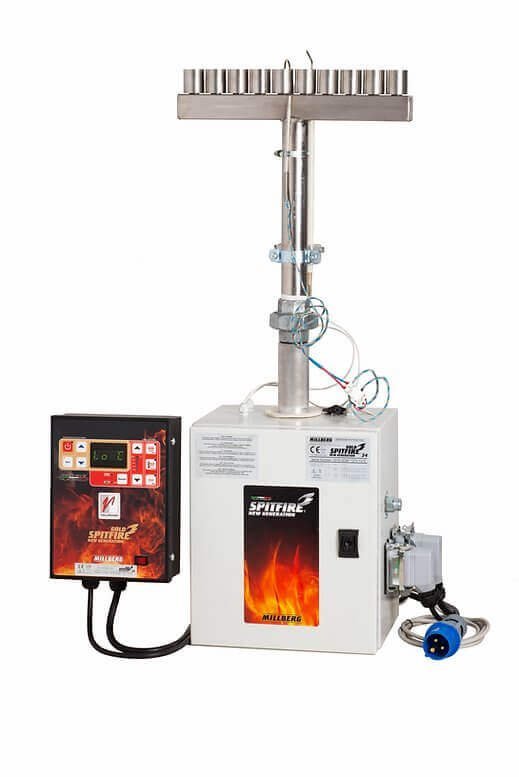

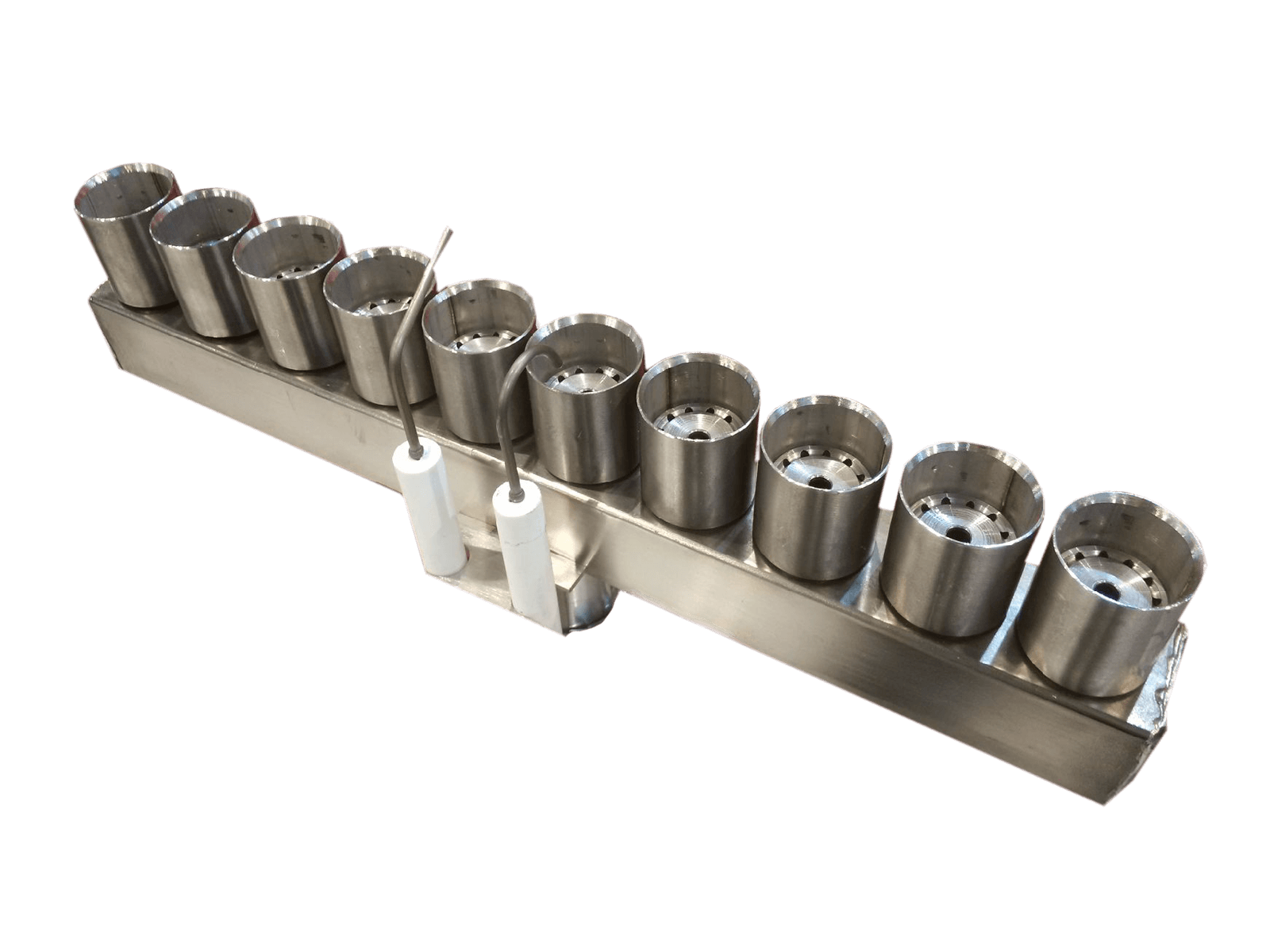

Gas burner for gastronomic ovens

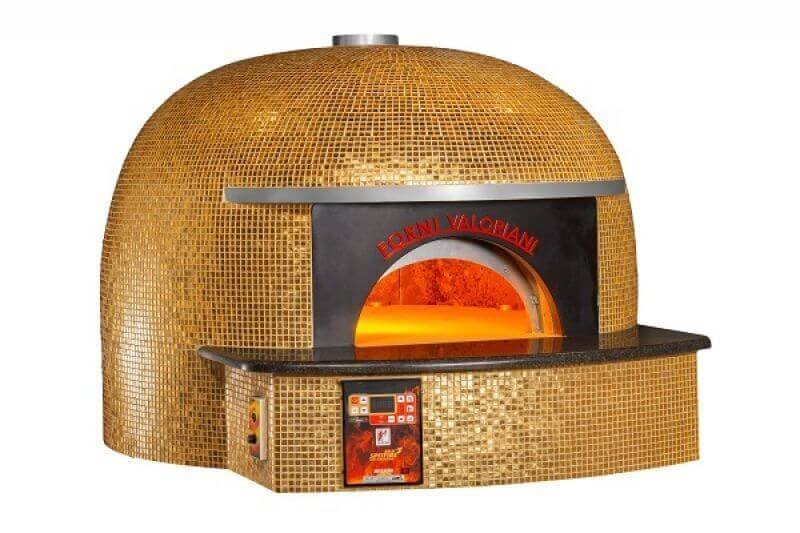

The Millberg blown gas burner Spitfire GOLD is suitable for gastronomic oven models up to an inner diameter of 160 to 180 cm. It is a 10-flame forced-air gas burner that swirls the hot air inside the oven and thus achieves up to 50% better energy yield compared to conventional atmospheric burners with one or two nozzles. Ideally, the Spitfire is operated in a Valoriani GR, OT and Igloo series pizza oven and can also be retrofitted at any time.

Efficient and economical:

The Spitfire GOLD is the ideal blower gas burner for professional use. The exhaust gas values of the ovens improve considerably. The low gas consumption of the Spitfire is also a great advantage. Compared to conventional gas burners, the Spitfire requires only 50% of the gas needed by a standard burner. These excellent values are achieved by the automatic control and the automatic blower. The operating costs are a maximum of 1 euro per hour.

Operating temperatures of up to 600 degrees are possible with the Spitfire. It has been tested and approved by DVGW and AVPN for original Neapolitan pizza. Indoors, the Spitfire can be operated with natural or liquid gas. Installation takes only 1 to 2 hours.

When purchasing gas-fired pizza ovens, please always refer to the operating instructions. You can also find tips and tricks on using gas pizza ovens in our magazine.

Equipment

- temperature control

- thermostat and temperature display

- Ventilation

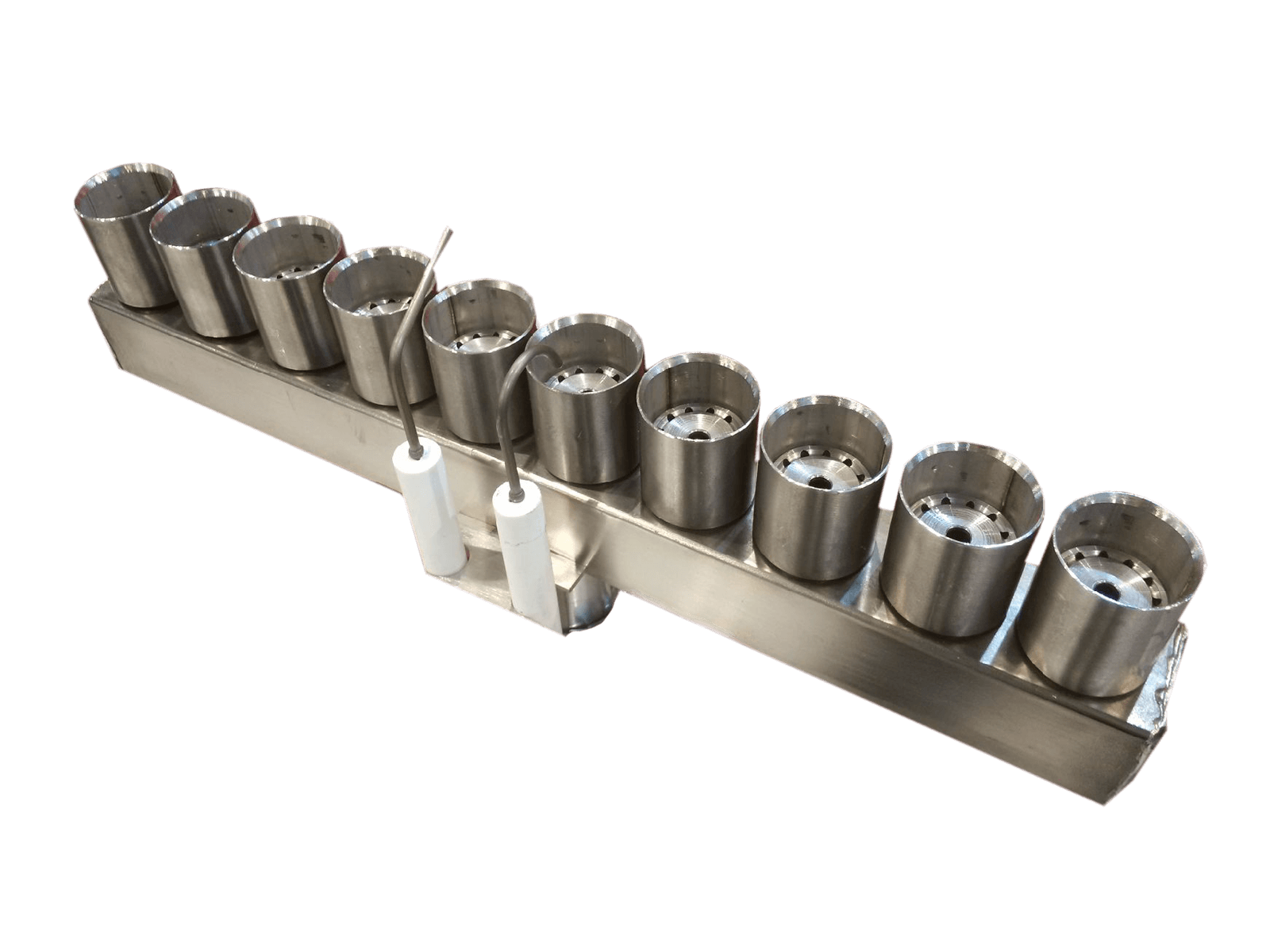

- 10-flame

- modulating flame,

- Can be mounted on the right or left

- Consumption max. approx. 1 Euro/hour

- Gas connection must be carried out by a gas fitter

- LPG (liquid gas) or natural gas possible

- Maximum output 29 KW or 34KW

- DVGW approved

- Hourly consumption 1-1.5 Nm³/h

- Inlet pressure minimum 10 to maximum 30 mbar.

- Gas connection pipe 1/2 inch

- Electrical voltage 220 V 50 Hz

- Manual and automatic control

Videos about Millberg ignition electrode

You might also like

Accessory Items